Downloads

- Trasco® ES couplings (1Mb)

- ATEX Annex (0,4Mb)

- Use and Maintenance Manual TRASCO® ES (2Mb)

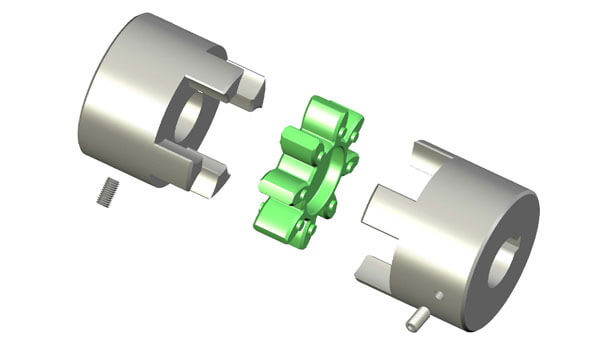

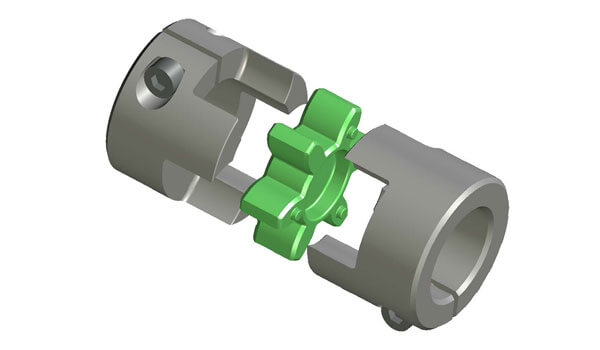

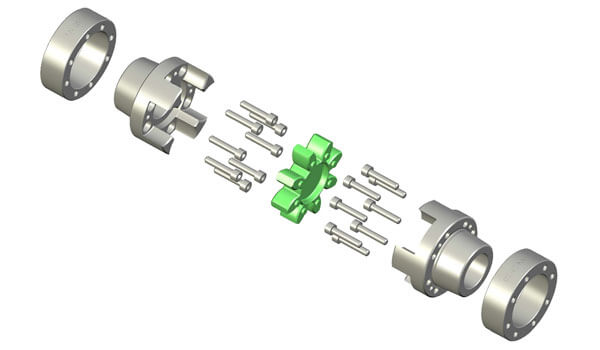

TRASCO® ES is our zero backlash coupling designed to compensate for misalignment and vibration dampening for indexing applications. The compact design of TRASCO® ES makes it the right choice for all precise motion applications. Absorbs shock and vibration through an elastomeric ring in different hardnesses.

SIT coupling hubs are available from stock with either solid hub or with finished bores of standard shaft diameters.

The set-screws of our finished bore execution are positioned 120 degrees from each other with one positioned 180 degrees from the keyway. Both the solid hub and bored hub coupling are generally available from stock for quick delivery. Approved according to EC standard ATEX.

Compact version of the GESM series with reduced overall length. They ensure the same performance as the normal version with reduced sizes.

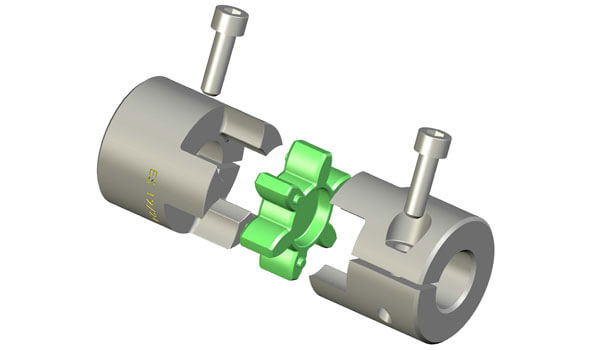

The clamped hub enables rapid and secure fastening shaft-hub with zero backlash.

Approved according to EC standard ATEX.

This type of coupling permits quick, positive mounting, without any shaft-hub backlash. With the keyless coupling type, the torque applied for tightening down the screws (Ms) must be as given in the table. The M coupling type is available with or without keyway. Approved according to EC standard ATEX.

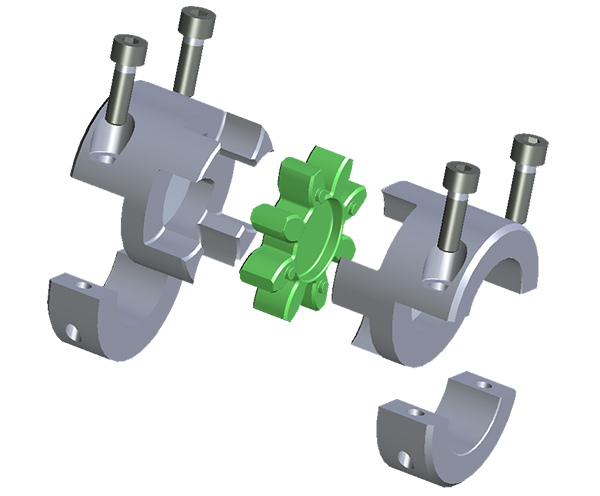

Slit clamping hub execution for radial assembly of the coupling torque depend on bore diameter. Approved according to EC standard ATEX.

This type of coupling provides excellent kinetic uniformity. Furthermore, the absence of keys or set screws makes it a well-balanced coupling and greatly facilitates installation and removal. An exact radial/axial positioning is easy for those applications which require it. The absence of keyways also avoids fretting corrosion and backlash between the shaft and the hub. This is the ideal type of coupling for applications requiring precision and/or high rotational speeds. Approved according to EC standard ATEX.

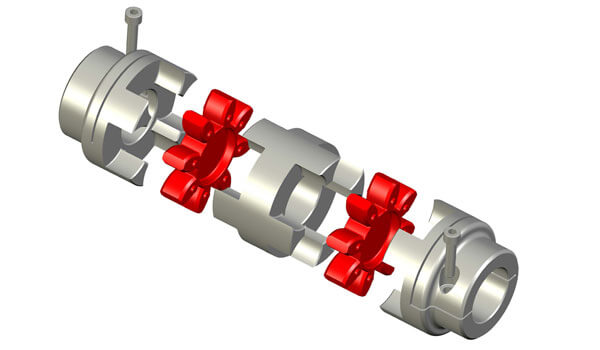

Precision “zero-backlash” coupling designed for multi spindle devices on machine tools or controls with reduced mass, such as short center spindles, multi-centers primary spindles in work stations, or joined to high speed bearings with limited tolerance range. It is suitable for very high speeds of rotation (up to speeds of 50 m/s).

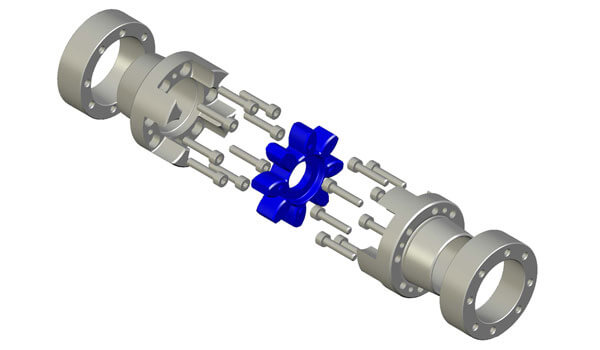

This execution allows higher misalignments. The 2 spiders allow a high vibration dampening providing a decrease in drive noise and longer life of related components (ex. bearings). The intermediate element is made of aluminum alloy and may be used in combination with any type of hub execution.

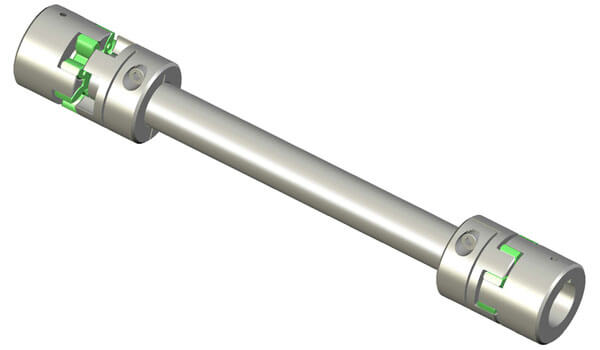

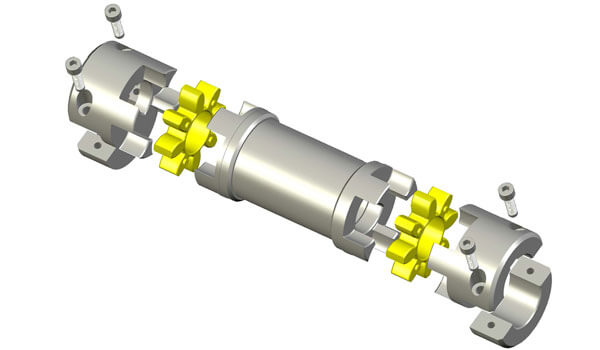

This zero backlash execution, allows connection to long distance shafts in applications such as lifting screw jacks, gantry robot etc. The intermediate shaft is made of steel but may be of different material for specific need.

The presence of 2 spiders, increases the dampening properties and allow high misalignments.

Ideal execution for long distance shaft connections. Torque transmission is zero backlash. It is used in applications such as automatic machines, lifting machines, palletizing machines, and handling machines. Designed for length up to 4 m without bearing support (depending on rotation speed). The double slot execution, allows spider mounting and replacement without driver/driven machine displacement. All aluminum alloy for a very low inertia.