Downloads

- Asahi® Ball Bearings (7,4Mb)

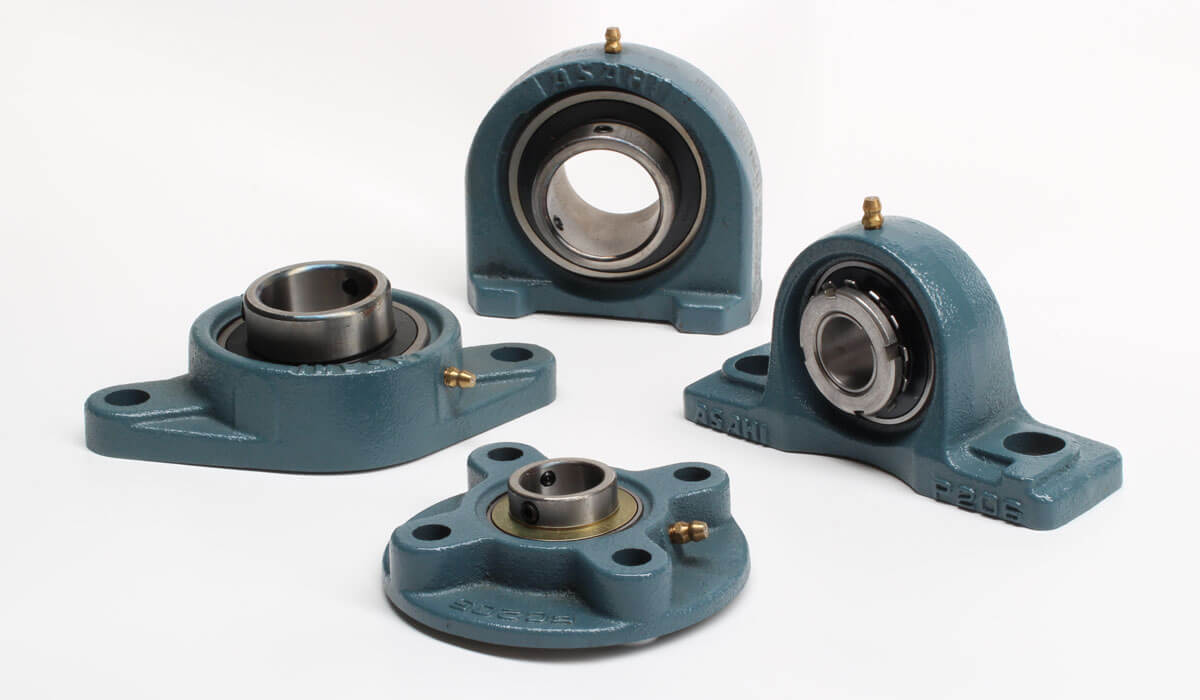

ASAHI® Japanese-manufactured bearing units are used in various application sectors. The monoblock bearing units are produced with an exclusive locking pin that enables self-alignment and prevents the rotation of the outer ring, thereby increasing the useful life of the installation.

The range is one of the largest in the world and includes bearing units with cast iron, stainless steel and stamped sheet metal bodies.

Bearing units are available designed for the insertion of a protective cap and for high-temperature applications and very high radial loads.

ASAHI® ball bearings Units and connecting rod ends are available with bronze, Teflon or steel-on-steel inserts

The very high machining quality and precision ensure the maximum reliability and durability in any application, including the most severe. For shaft diameters of between Ø 12 and Ø 140 mm.

An enormous range of versions with cast iron bodies for generic applications.

Can be supplied with ball-bearings:

Version with stamped and galvanized sheet metal for economical, low-load applications.

For shaft diameters of between Ø 12 and Ø 35 mm. Available with type B ball-bearings with lifelong lubrication for generic applications.

Versions in stainless steel, perfect for applications in the food and packaging sector, where very aggressive, high-humidity environments can be found, due to their excellent resistance to corrosion.

Can be supplied with FDA-standard grease. For shaft diameters of between Ø 12 and Ø 50 mm.

With MUC type ball-bearings, these bearing units are entirely made of stainless steel and have a vast operating temperature range from -20 °C to +120 °C.

Manufactured with a special zinc alloy body and stainless steel AISI 304 bearing, designed for use in potentially corrosive applications, combing maximum lightness with quick and accurate mounting, thanks to the marking of the centre distances. Suitable for working at temperatures between -10 °C and +80 °C.

They are very small in size, for shaft diameters of between Ø 10 and Ø 30 mm.

Ball joints and connecting rod ends with bronze, Teflon or steel-on-steel inserts. Steel-on-steel and steel-on-aluminium 90-degree ball joints. Weld-on ends for hydraulic cylinders.

Characteristics