Downloads

- Steel flat belts (2 Mb)

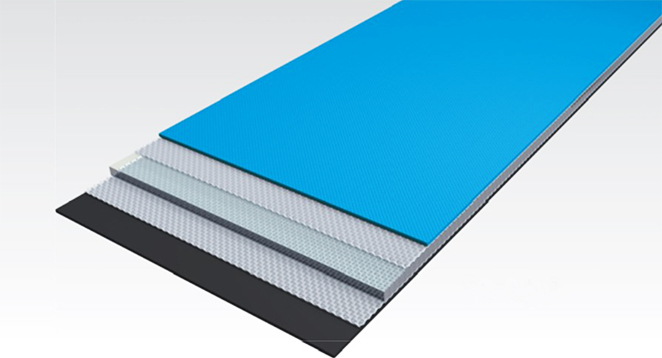

This monofilament polyamide core flat belt range is combined with a wide choice of covers for wear and abrasion resistance. With a skived jointing system using glue, this range provides the ultimate joint reliability for the user.

Due to the excellent performance, durability and quality, this Nitta range is ideal for demanding applications in the textile, paper processing and printing industries. Customer demands are consistently being fulfilled by new developments using polyamide and own manufactured elastomers.

Pulleys made in according to customer drawing.

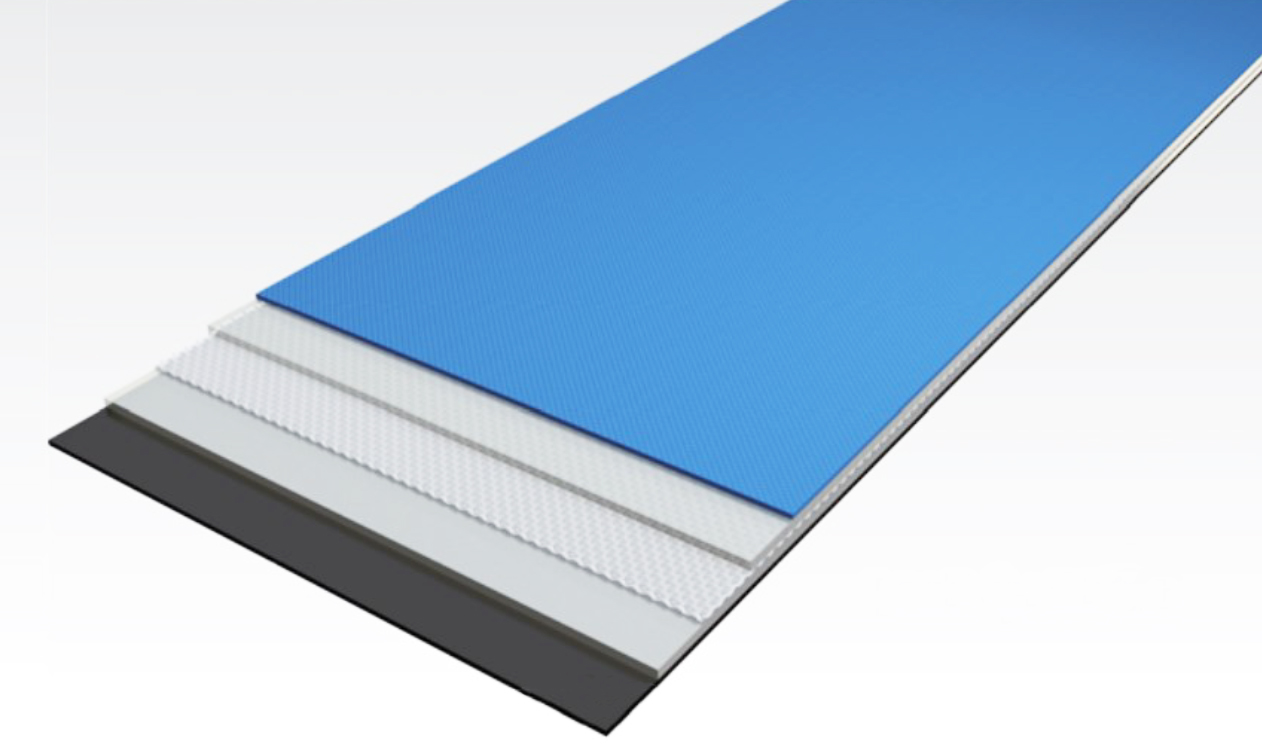

Produced using a wide variety of material combinations such as thermoplastic polyurethane, nitrile rubber and elastic fabrics and featuring varied surface constructions from smooth to structured.

Easy and fast finger jointing system without using any glue, this range provides excellent dimension stability and is highly suitable for small pulley diameters. Nitta PolySprint™ belts are suitable for high speed and use the unique Nitta NBR rubber with fine textured surfaces.

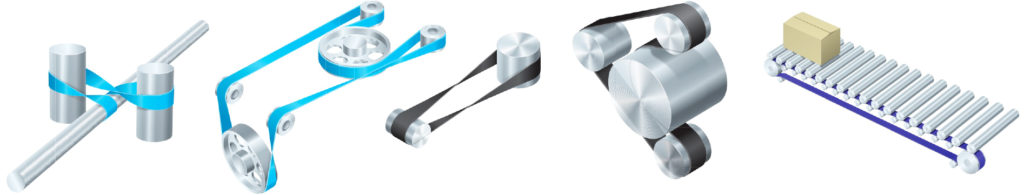

Our PolySprint™ range of belts is ideal for feeding, folding and packaging and are installed in printing (web) folders, print finishing applications, packaging machines, live roller and textile applications.

Pulleys made in according to customer drawing.

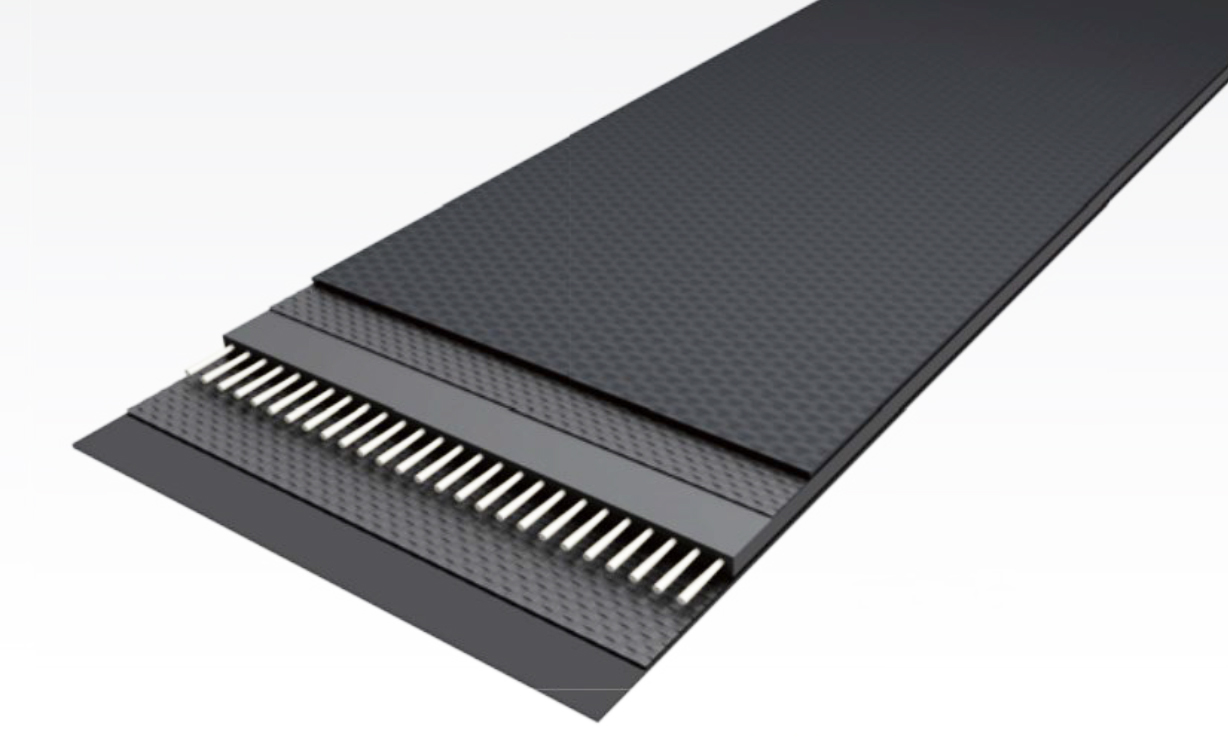

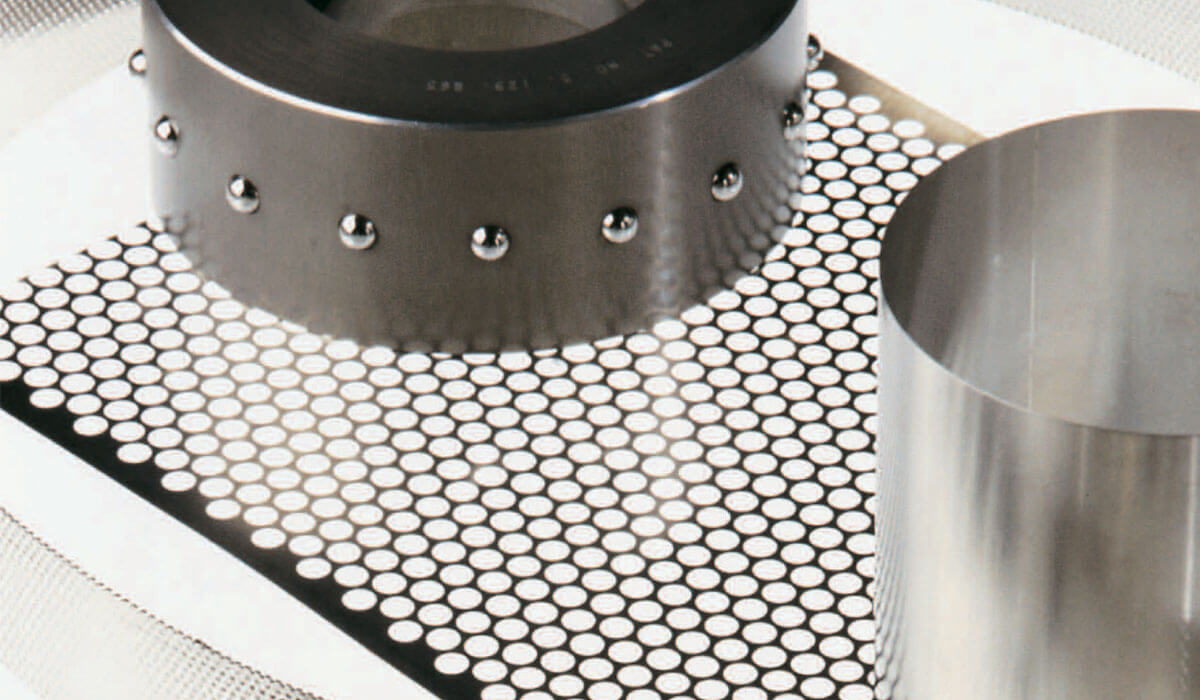

Thin and of light construction, this range provides seamless belts with excellent dimension consistency which are energy saving, highly accurate, ultra-flexible and abrasion resistant, anti-static, low noise and maintenance free.

Nitta SEB™ (Super Endless Belt) range is installed in banking equipment such as ATMs, postal sorting machines, office equipment, printing machines, paper handling applications, ticket dispensers, check weighers and centrifugal drives.

Metal belts have a high strength-to-weight ratio, withstand sustained exposure to extremes of temperature, hostile environments and vacuum, do not require lubrication, do not generate dust, do not elongate and have regular operation.