Other link

Thanks to top-quality, state-of-the-art machinery and techniques such as water jet cutting, ELATECH® timing belts can be mechanically processed to perform special and complex tasks. The extremely precise machining and finishing operations guarantee the respect of the strictest tolerance requirements and the maximum reliability of ELATECH® timing belts in all the most complex and demanding industrial applications.

Benefits

- Unique solution

- Customization

- Technical/economic optimization

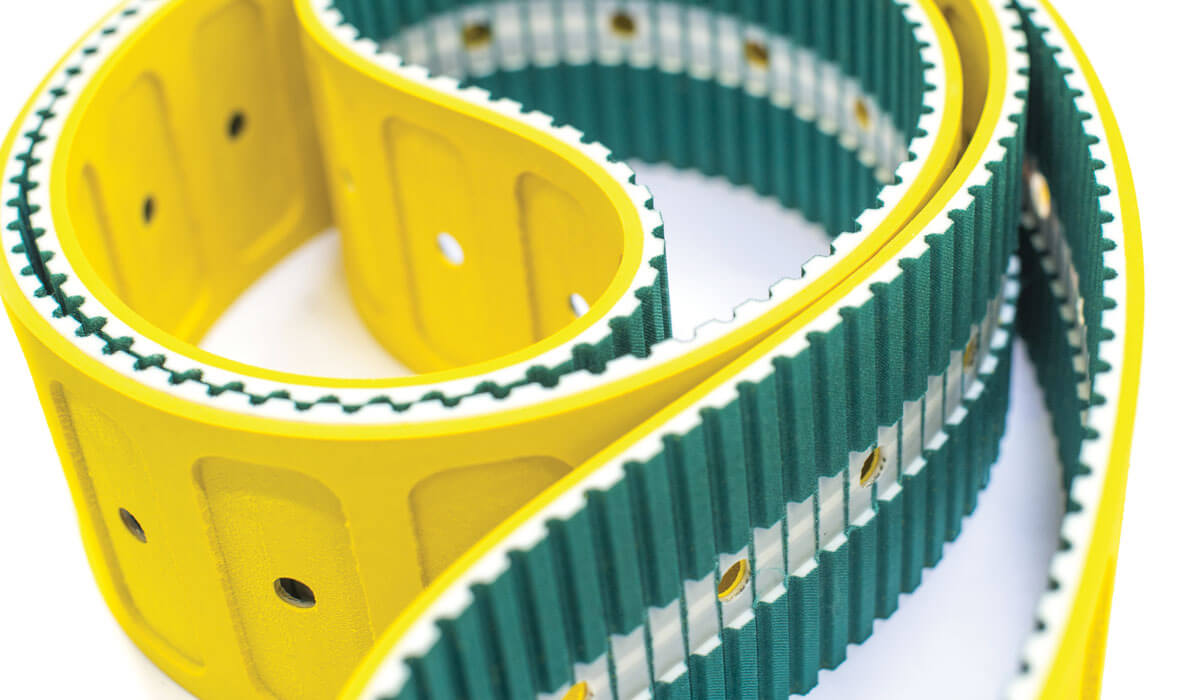

Customized polyurethane belts solutions

Belts with Coatings (Fabric, Cellular, Elastomeric, Polyurethane, PVC, Rubber, Special)

ELATECH® offers a wide range of materials that can be applied on the back of the belts in order to optimize the performance in even the most complex conveying applications.

The wide range of Elatech coatings can be divided into 6 categories: fabric, foam cell, polyurethane, PVC, rubber and special. Each of these categories is geared to meet the best performance for specific applications. It is also possible to combine coatings to cleats, machining or complex drilling that Elatech realizes with water jet technology.

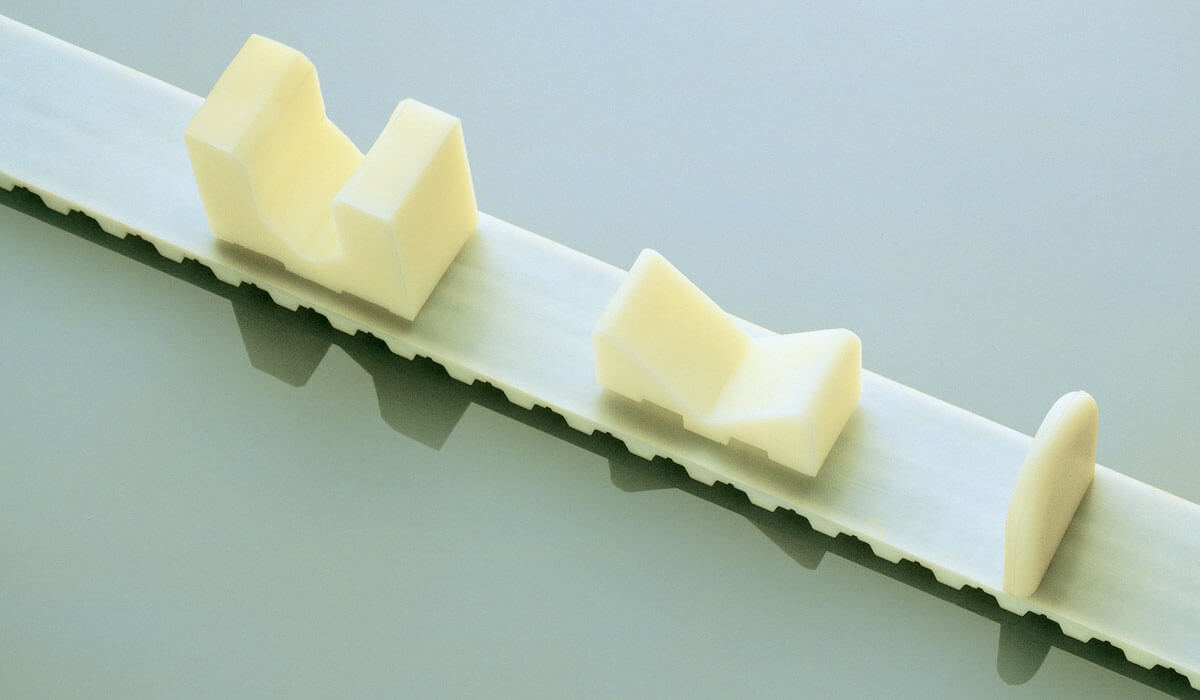

Belts with Cleats

The application of a great variety of Cleats on the back of Elatech belts is possible for various transport applications. The cleats are produced both in the same material of the belts, so as to ensure the maximum resistance, and in special materials. The cleats applied with the Elatech technology form a single body with the belt and guarantee the maximum resistance during the operating cycle. ELATECH® belts with cleats are the ideal solution for synchronized conveying of products when precision, high operating speed and low noise is required.

Consult the ElaCleats online software that offers hundreds of available cleats. Our team of engineers are available to develop customized solutions for specific applications.

Belts with EMF mechanical fastening system

The EMF system is a practical and functional mechanical fastening system which allows quick installation or replacement of endless belts without disassembling parts of the machine and without the aid of specific equipment. This results in time saving and consequent maintenance cost reduction. The EMF system applies to all profiles (EAGLE excluded).

Belts with EFT mechanical profile system

ELATECH® EFT system is offered in zinc coated or stainless-steel teeth with either embedded tooth or total tooth design. The application of profiles in different materials from the belt body (steel, polyamide, POM, wood, etc.) and in virtually any dimension is possible. The belt tooth is replaced by a false tooth in galvanized or stainless steel.

EFT belts are available in two executions:

- Total Tooth Design: the polyurethane tooth is entirely replaced by a steel tooth;

- Embedded Tooth Design: it prevents metal to metal contact and reduces noise.

Machining processes on polyurethane belts

ELATECH® helps the designer in choosing the most suitable product even when the belt needs complex precision machining.

In fact, due to the latest generation of specific equipment and most modern technologies such as water jet, Elatech may propose specific added value solution for any application.