ELAClean® SIT-ELATECH belts are a new range of monolithic belts made of homogeneous, thermoplastic polyurethane, specifically designed for food contact and suitable to meet the required hygiene standards. They are available in various profiles and surface finishing, ensuring quality, precision and customizations for a wide range of applications.

All ELAClean® SIT-ELATECH belts can withstand oil, grease, cleaning agents, bacteria, making them exceptionally easy to clean and suitable in critical hygiene applications (e. g. when processing meat, poultry or seafood, dough and fresh dairy products). In addition to those benefits, ELAClean® belts can be also customized (e. g. with profiles, flights and sidewalls) to handle a wide range of conveying jobs.

ELAClean® meets the requirements of the food industry in terms of efficiency, safety, and compliance with regulatory standards, offering:

- Reduced downtime for maintenance and replacement thanks to the high-performance polyurethane that minimizes the risk of belt failure due to tear and wear;

- Easy cleaning, maintenance and increased overall hygiene of the food production environment, thanks to the smooth and seamless surface;

- Durability and reliability of conveying surface that ensuring an efficient flow of materials throughout the production line.

ELAClean® range includes:

– Positive drive belts tooth pitch 26mm (EC-P1)

– Positive drive belts tooth pitch 50mm (EC-P2)

– Self centering positive drive belt tooth pitch: 39.7mm (EC-C4)

– Flat belts belt thickness: 3mm (EC-F3)

Each one of these can be provided with specific surface finishing, according to different application needs.

- Glossy surface: excellent cut resistance, good product adherence, suitable for incline and decline conveying, improve precise positioning (dry/semi-dry products);

- Matte surface: good product release, suitable for product highspeed conveying operations;

- No-Cling surface: excellent release properties, recommended for incline and decline conveying and prevent vacuum effect.

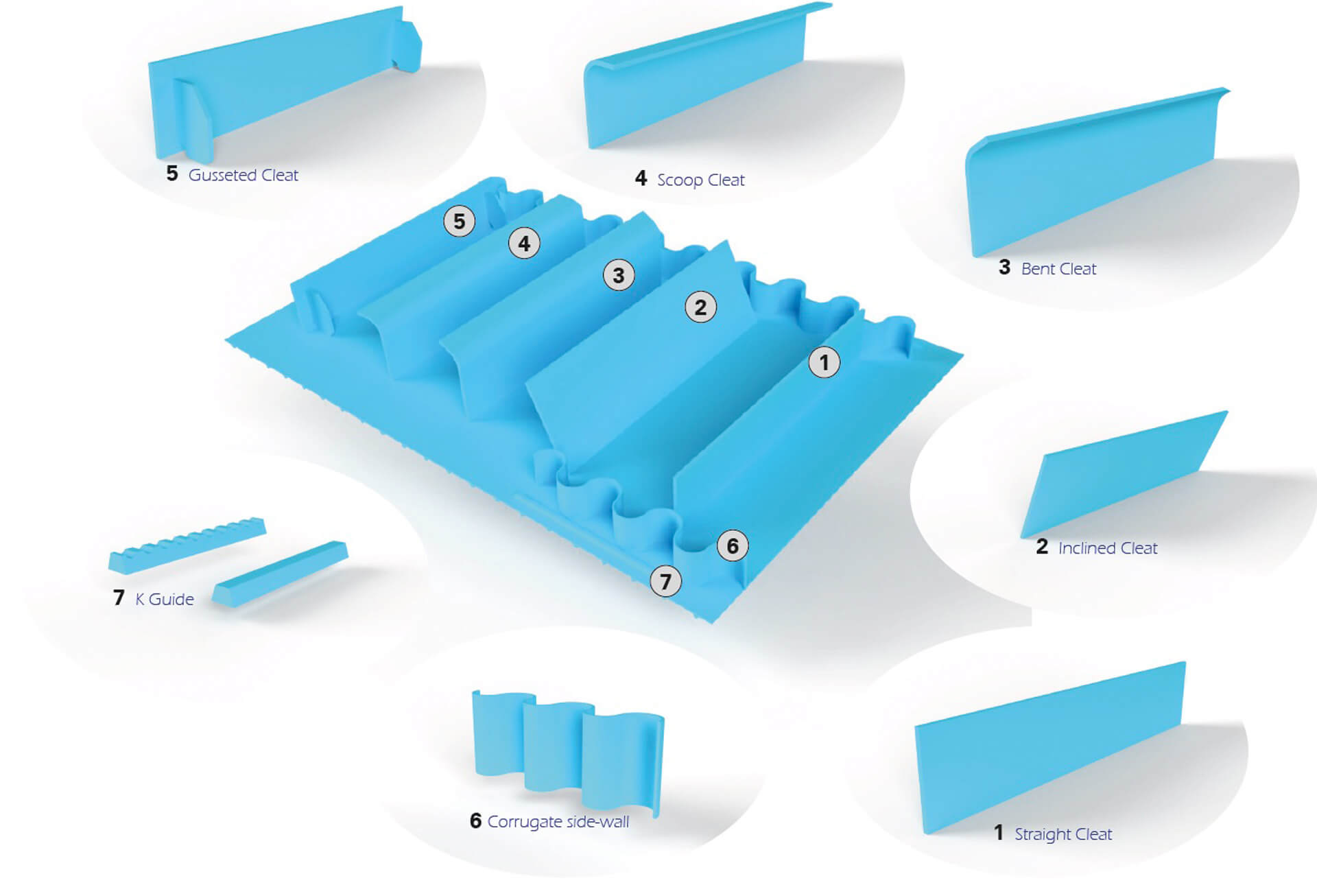

ELAClean® customization options available:

- Accessories for the belt (straight cleats, inclined cleats, scoop cleats, v-guides and corrugate sidewalls);

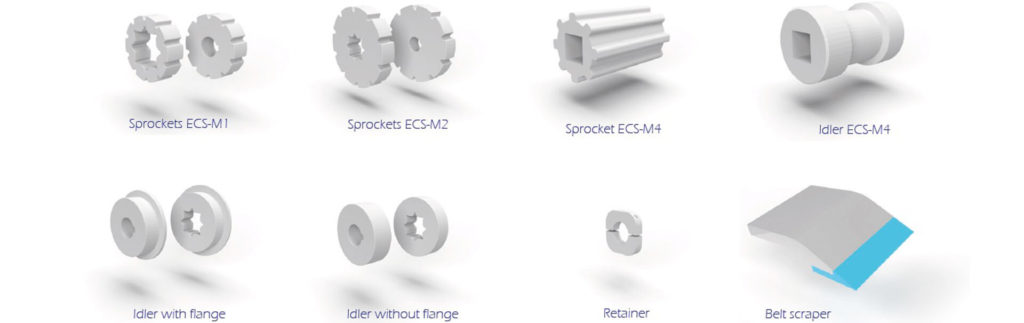

- Accessories for the conveyor (sprockets, rollers, idler, retainer rings and adaptors);

- Tools for the transformation and customization.

Mechanical and chemical product properties and characteristics

- Possibility of easy and effective clean-in-place process (CIP);

- Urethane material compatible with wash down environments;

- No fragmenting or chipping, compared with modular belts;

- Environmental sustainability thanks to the reduction of cleaning labour, energy and water usage;

- Reduced maintenance and sanitation costs and reduced downtime;

- Sprockets compatibility: drop-in replacement for most thermoplastic belts in the market;

- Ideal for replacement of plastic modular belts;

- Longer belt life due to minimal belt stretch.

Customize the belt with the most suitable configuration according to your application needs

- Dowels (straight, inclined or curve; radiused or with a sharp edge);

- Flexible side wall;

- K Guides (solid or notched)

- Scrapers

- Toothed and smart pinions;

- Support Rolls;

- Clamp for fixation of pinions;

- Hole shaft adaptors;

- Elements for mechanical joints (plastic or metal).