Other link

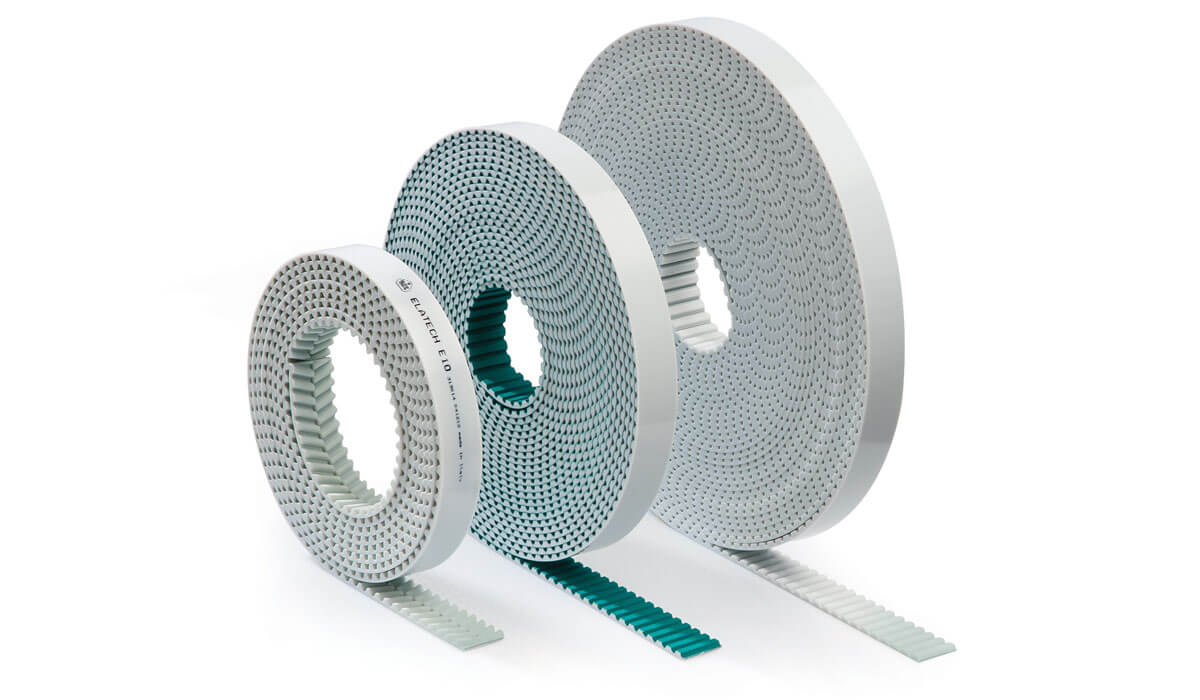

ELATECH® M open end belts are produced in standard roll length of 100 meters and delivered to any desired length. The excellent precision and dimensional stability and the high abrasion resistance make them ideal in all linear motion applications.

ELATECH® V are jointed belts obtained from open-end belts. The special manufacturing process, allows for obtaining any desired length. Due to the high flexibility and to the unique precision in positioning offered, ELATECH® V belts are ideal for all conveying applications where synchronization is needed.

Belt characteristics

- Pitch:

- T (2,5 – 5 – 10 – 20) | AT (3 – 5 – 10 – 20) | SAT (10)

- TK5-K6 – TK10-K6 – TK10-K13 (SELF CENTERING) | ATK5-K6 – ATK10-K6 – ATK10-K13 (SELF CENTERING)

- MXL – XL – L – H – XH

- HTD (3 – 5 – 8 – 14) | RTD (5 – 8 – 14) | STD (5 – 8 – 14)

- EAGLE (5 – 8 – 10 – 14)

- FLAT (1 – 2 – 2,5 – 3 – 9)

- POLY-V K

- T10 – AT10 – HTD8 – Total Protection | TT5

- Double sided tooth construction available

- Antistatic properties according to ISO 9563

- Certified to be according RoHS 2011/65/UE

- Working temperatures between: -25°C to + 80°C

- Tension cords: steel with high tensile strength (Special cords on request)

- Compound: thermoplastic polyurethane 92 Sh. A with high wear resistance

Benifits

- Excellent length stability

- High abrasion resistance

- Maintenance free

- High linear and angular positioning precision

Available with standard pulleys in aluminum, cast iron or steel, with solid hub, for mounting SER-SIT® taper bushing or according to customer specifications.

Wide range of timing bars available on stock.

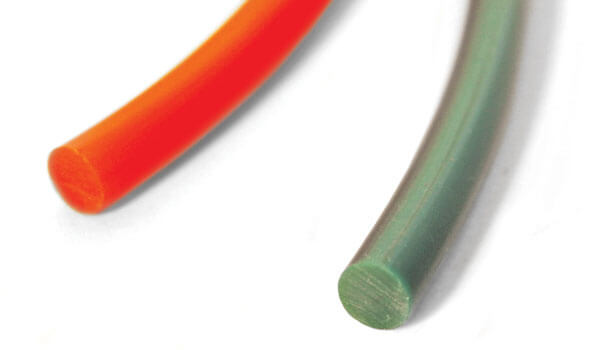

REDTHANE e GREENTHANE Polyurethane Belts

REDTHANE e GREENTHANE Polyurethane Belts

Redthane and Greenthane Belts (0,1Mb)

The REDTHANE and GREENTHANE polyurethane belts can be closed in ring by welding or by using the patent fastener.

The belts are produced by the meter in any lengths and with different diameters.

On request it is possible to supply different hardnesses.